Table of Contents

Installation

Inspecting the delivery

- Check the device immediately as soon as it is delivered for completeness in accordance with the delivery note and also for visible damages incurred during transport.

- In order to retain the right of recourse, report any shipping damages immediately in writing to the forwarding agent, the insurance company and Smarten Electric。

Disposing of packaging material

If you do not want to keep the packaging material for a subsequent transport, Dispose of all packaging materials in compliance with the relevant regional waste disposal regulations

Transport

⚠CAUTION!

Risk of injury due to the weight of the device

- Do not carry or lift the device alone.

- Do not use protruding parts to lift the device.

- Lift device using suitable lifting gear.

NOTICE!

Damage to impact-sensitive components

If the device is set down heavily or tips over, impact sensitive components inside the device will be damaged (e.g. fans, circuit boards).

- Do not set down the device heavily or drop it.

- Stand the device on its underside or on its side.

- If necessary, secure the device against tipping over

Storage conditions

If you do not install the device immediately following delivery:

- Store the device in original packaging.

- Ensure that the specified environmental conditions are maintained.

Requirements for the site

Installation requirements

- Though designed to be weather proof, operation is recommended in a closed electrical operating space with proper ventilation.

- Installation, mounting and operation according to IEC 62109-2:

- Access restriction for the electrical operating room.

- Only electrically instructed persons may work within the operating room.

- If the specified operating conditions for Smarten Power are observed, it is permissible to forgo residual current devices RCD) unless country-specific requirements state otherwise.

If necessary, post a notice at the electrical operating room indicating that these are not present.

- According to IEC 62477-1, installation, mounting and operation are only permissible in:

- Non-flammable environment.

- Indoors with air conditioning

Air intake and air outlet

Sufficient space must be present for air intake and air outlet in order to ensure adequate cooling of the device.

Maximum back pressure

Cooling of the module is only ensured if a certain air flow rate up to a maximum permissible back pressure is available.

When operating several modules, the air flow rate is to be multiplied by the number of devices.

Air short circuits and mutual interference of the modules must be prevented.

Mains separation device

Access to the external mains separation device must not be obstructed by the device.

Fuses

Fuses must be provided on-site by the customer

Residual current device

If a Smarten Power 150 is or multiple devices are operated together with a DC-coupled energy system that is not electrically isolated, a suitable residual current device must be installed depending on the installation location of the system. Observe all country-specific requirements regarding location and installation.

- Install a type B residual current device (RCD or similar).

- Maximum permissible continuous residual current (IEC 62109-2:2011 Sec.4.8.3.5):

- Single installation: 300 mA.

- Multiple installation within a system: 10 mA per 1 kVA nominal output power.

- Separation time of outer conductors and/or neutral conductor: 0.3 s.

- Determine the rated current specifications corresponding to the system layout.

- Set up the residual current devices in accordance with the country-specific grid frequencies and grid voltages.

Ground fault and leakage current monitoring

- The Smarten Power 150 has integrated residual current monitoring.

- For multiple module Interated in one system, extra leakage current monitoring device must be implemented.

- If the device is used in a battery energy storage system (BESS), the technical specifications of the system integrator and of the respective system manual with respect to ground fault and leakage current monitoring must be observed.

Dependent safety requirements

The Smarten Power 150 is a transformerless inverter:

- Without internal voltage isolation.

- Without integrated, automatic separation device.

- Without integrated residual current device.

The implementation of, compliance with and monitoring of the dependent safety requirements lies solely and completely with the responsible system operator or a third party commissioned by the system operator

Installation-wall mounting

A wall mounting bracket is included in the package

Tools and material:

- drill or electric hammer

- 10mm drill bit

- wrench

- expansion bolts 10mm x 4

⚠WARNING!

The converter module is heavy!

- It requires at least two persons to mount the converter module

The wall or the mechanical structure must be sufficient to bear the weight of the converter

- install the bracket with 2x expansion bolts

- fix the bottom of the converter with another 2x extension bolts

Installation-rack mounting

The size of Smarten Power 150 is NOT fitting 19 inch cabinets.

for rack mounting, the customer can either

- Design their own rack or cabinet

- Mount the converter on top of the battery rack

- Contact Smarten Electric to provide customized racks that can fit the converter with or without the battery modules.

Electrical connection

⚠DANGER!

Connection cables carry life threatening voltage!

- Do not work under voltage.

- Before connecting, check mains cables to ensure that they are not electrically live.

- Before connecting, check DC link (DC Link) voltage cables to ensure that they are not electrically live.

⚠DANGER!

Danger of fire!

- Observe the installation regulations of the installation site.

- Fuse the DC link connection (DC Link) according to the specifications

- The following applies to UL-bound countries: The “National Electrical Code, ANSI/NFPA 70” wiring methods are to be used.

NOTICE!

Failure to observe the torques can damage the converter module!

- Note torques when screwing.

NOTICE!

Observe regional requirements for the grid connection!

- The following applies to UL-bound countries: The “National Electrical Code, ANSI/NFPA 70” wiring methods are to be used

Establishing electrical connection

Means, Tools, Materials

- Terminating resistor for the data output (provided).

- Male connector (provided):

- Connector Mains, 5-pin

- Connector Contactor / Mains Measurement, 10-pin

- Connector DC Link, 3-pin

- Connector 24V, 2-pin

Note

Observe regional requirements for the grid connection! The regional requirements must be clarified at the customer’s location with the mains operator before the device is connected and commissioned

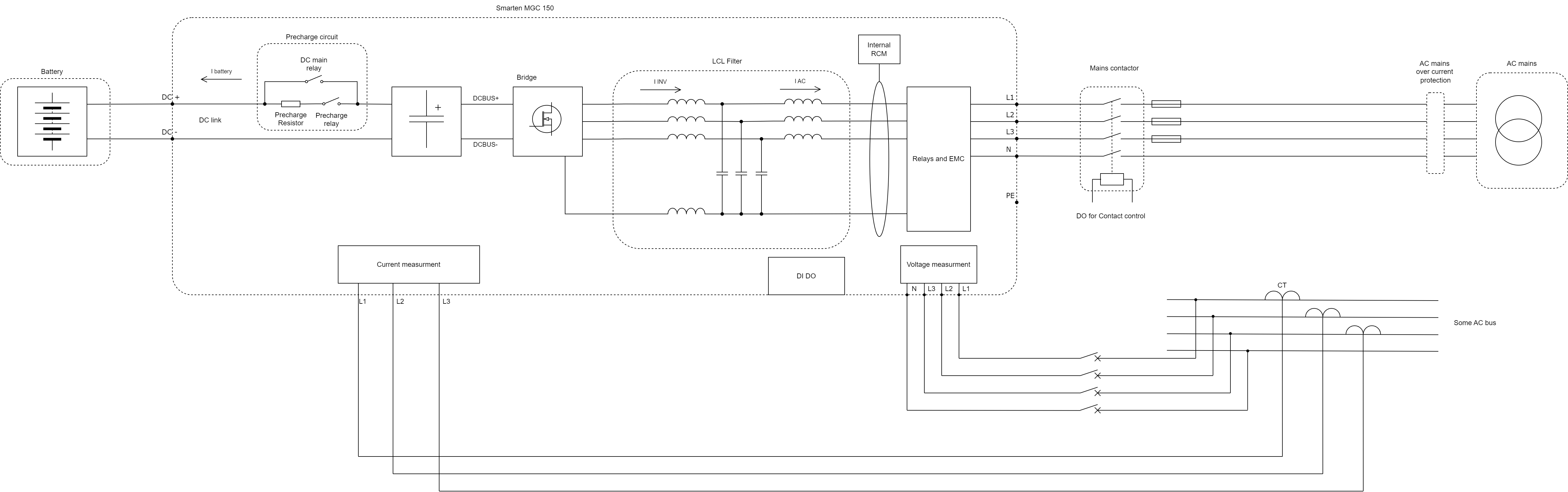

Connection diagram

Customer area

The following components are not part of the AC-DC module, but must rather be provided by the customer:

- Australia and New Zealand: Observe the special requirements regarding installation (see “Connection according to AS/NZS 4777.2”).

- Mains and system protection (*) (If residual current devices are used: use type B.)

- Fuses / power circuit breakers (*)

- Mains contactor (5) − Dielectric strength corresponding to mains voltage: 400 / 480 V ±10%

- Current-carrying capacity: 64 A

- Operation mode: AC-3

- Circuit breaker for mains voltage measurement (9) (see “Interfaces”)

- Connection of energy sources to the DC link (7) Observe the country-specific requirements regarding the installation of external mains separation devices.

Note

Observe regional requirements for the mains connection!

The regional requirements must be clarified at the customer’s location with the mains operator before the device is connected and commissioned.

Connection according to AS/NZS 4777.2

Requirements for grid-forming mode

The device can be used as a grid-following inverter and as a grid-forming inverter. As a grid-forming inverter, it can be operated with up to * parallel units independently of the public grid. The device can form a stand-alone network on its own or together with other inverters (island operation).

Note

The function as “uninterruptible power supply” is not fulfilled and is not permissible

Load cases in grid-forming mode

Permissible load cases:

- Resistive-symmetric three-phase alternating current load.

- Three-phase alternating current motors in star and/or delta configuration.

- 1-phase loads (resistive-inductive or capacitive-motoric).

- Unbalanced load with 1-phase loads:

- A maximum unbalanced load of * kVA between the phases should not be exceeded. The value is recommended based on normative requirements regarding connection to public low-voltage grids.

- The device is designed for a maximum unbalanced load of * kVA between the phases.

NOTICE!

Excessive current on the neutral conductor leads to permanent DAMAGE of the device!

- Ensure that the nominal current on the neutral conductor is not exceeded in the case of asymmetries.

Impermissible load cases:

- Electrical loads that must ensure personal safety.

- Preservation of the electrical supply of medical devices of every type.

- Loads that could result in property and system damage if the stand-alone network is impaired.

In the event of questions regarding the general voltage supply in the stand-alone network through Smarten Power 150 or for the implementation of load cases that are not listed here, contact Smarten Electric service.

Permissible system types in grid-forming mode

A system consisting of Smarten Power 150 may be operated in grid-forming mode in the following system configurations:

- TN-S system.

- TN-C-S system.

The corresponding system images are shown in VDE-AR-E-2510-2:2015-09 Appendix B

Observe the following points:

- N conductor and PE conductor are not connected in the Smarten Power 150

- N conductor and PE conductor must be connected outside of the Smarten Power 150

Central earthing point in stand-alone network

If the converter is alternately operated parallel to the public grid and within a stand-alone network, a central earthing point (CEP) must be provided within the stand-alone network.

The current-carrying capacity up to the CEP must also be ensured.

In order to provide a CEP as soon as the connection to the pubic grid is disconnected and switches to island operation, it may be necessary to install an earthing switch.

Example:

If the inverter is disconnected at all poles (L1, L2, L3, N) from a grid in the TNC-S system, operation as a stand-alone network is only possible if the N-PE connection is restored using an earth selector switch

Electrical protection devices in grid-forming mode

The setup of low-voltage systems with an isolated supply must satisfy the requirements of DIN VDE 0100-100 or the corresponding country-specific regulations.

Dismantling

⚠WARNING!

Connection cables carry life threatening voltage!

- Open the external mains separation device between mains and the power connection of the device.

- De-energize the cable between mains and the mains synchronization connection.

- De-energize the connection cables to the DC link voltage.

- Maintain discharging time: at least 5 min.

⚠WARNING!

Dangerous residual voltage!

- Maintain discharging time: at least 5 min.

- Open external mains separation device.

- De-energize the connection cables to the DC link voltage.

- Check mains cable and DC link-voltage cable to ensure that they are not electrically live.

- At power connection Mains:

- Undo the screws.

- Disconnect mains cable.

- At DC link connection:

- Unlock the connectors.

- Disconnect the DC link cable.

- At connection for DI/DO and mains voltage measurement:

- Release the automatic locking mechanism.

- Disconnect the cable for mains voltage measurement / DI /DO.

- Disconnect data cable.

- Unscrew and remove the equipotential conductor if necessary

Shipping the module

Use packaging material which can withstand transport stresses to ship the module.

If the original packaging is no longer available: Suitable packaging material can be purchased from Smarten Electric.

Disposing of the module

Observe the local regulations when disposing of the module.